We are Channel Infrastructure

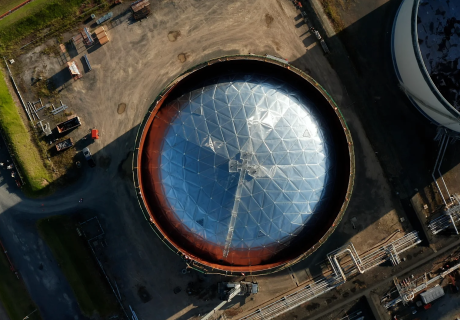

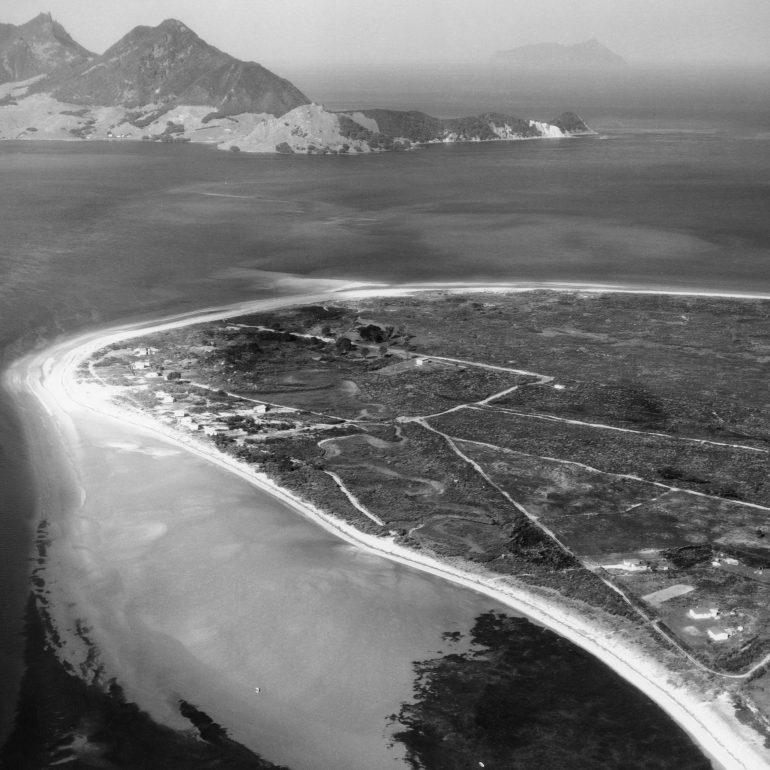

New Zealand’s leading fuel infrastructure company, based at Marsden Point, in Northland. We are an import terminal for the fuel needed to power New Zealand’s economy.

What We Do

Channel Infrastructure is New Zealand’s leading independent fuel infrastructure company.

Future Growth

Channel Infrastructure will have a key role to play as New Zealand’s fuel needs continue to change and we all look for new energy solutions.